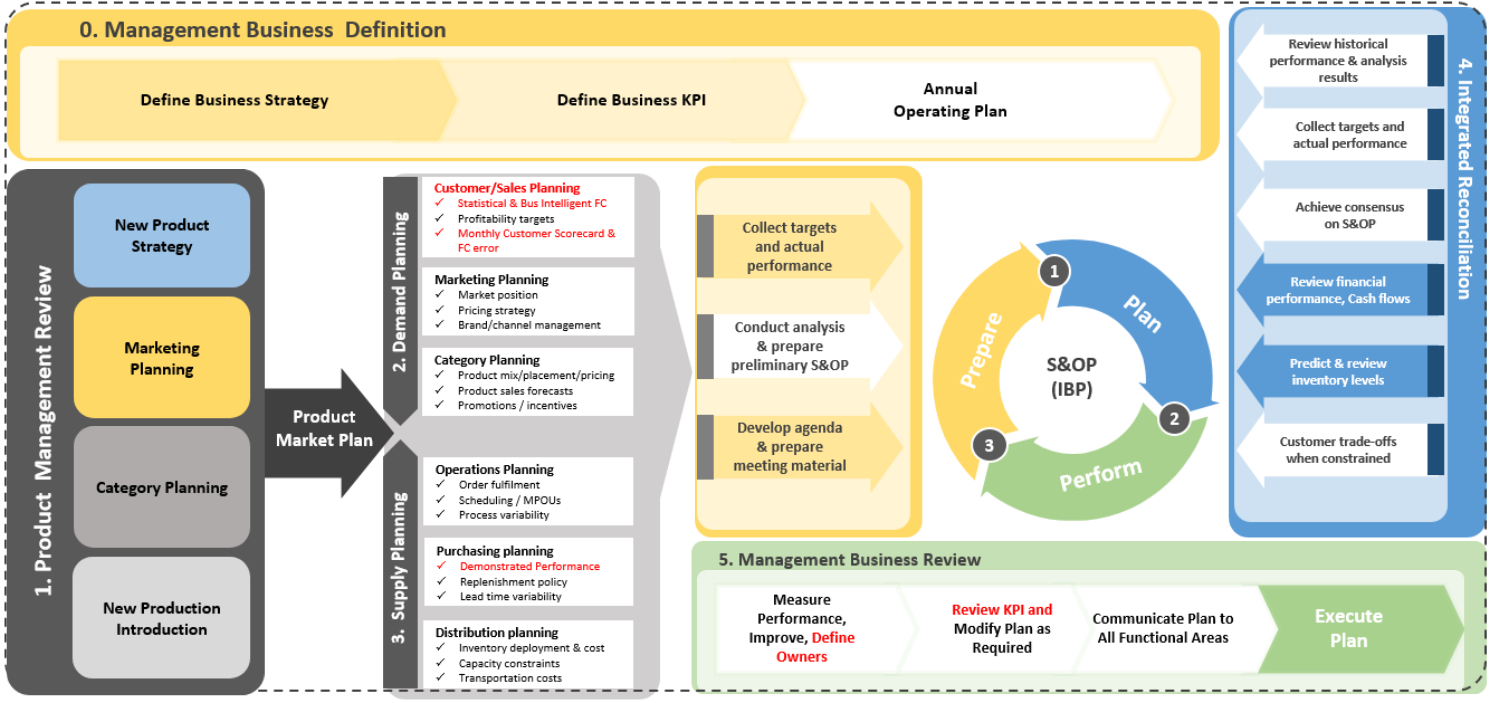

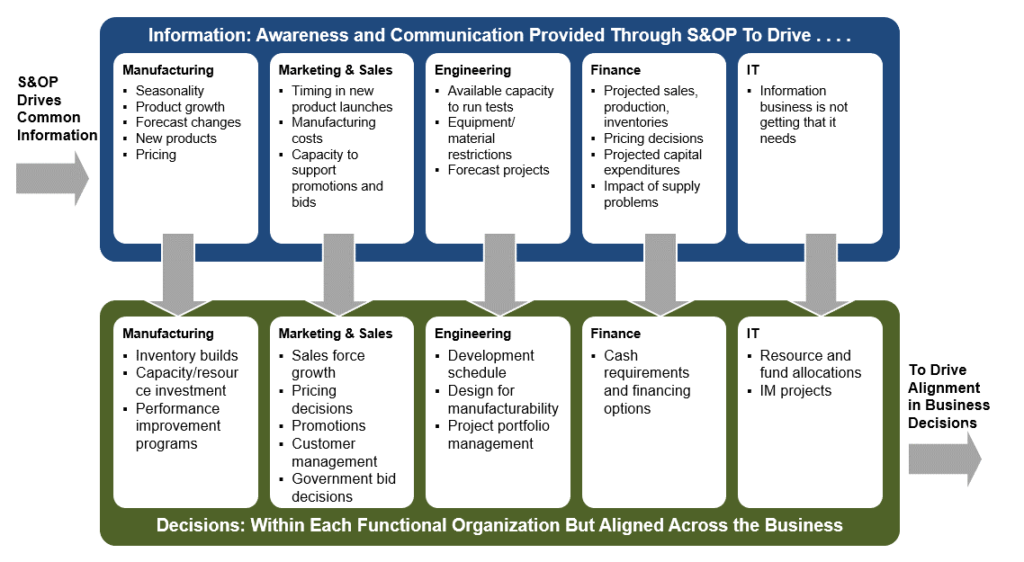

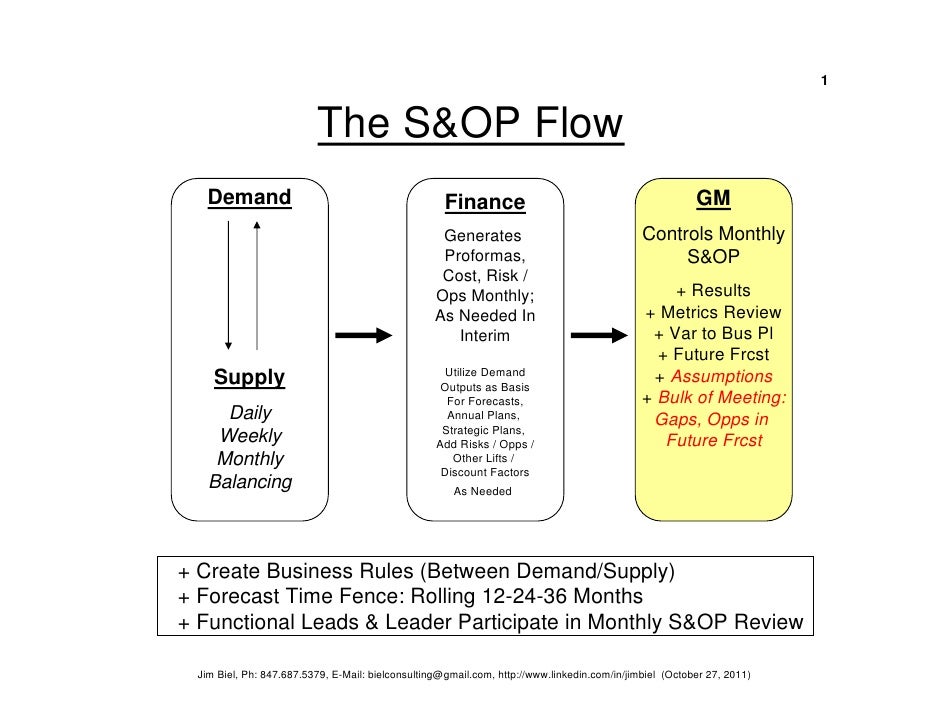

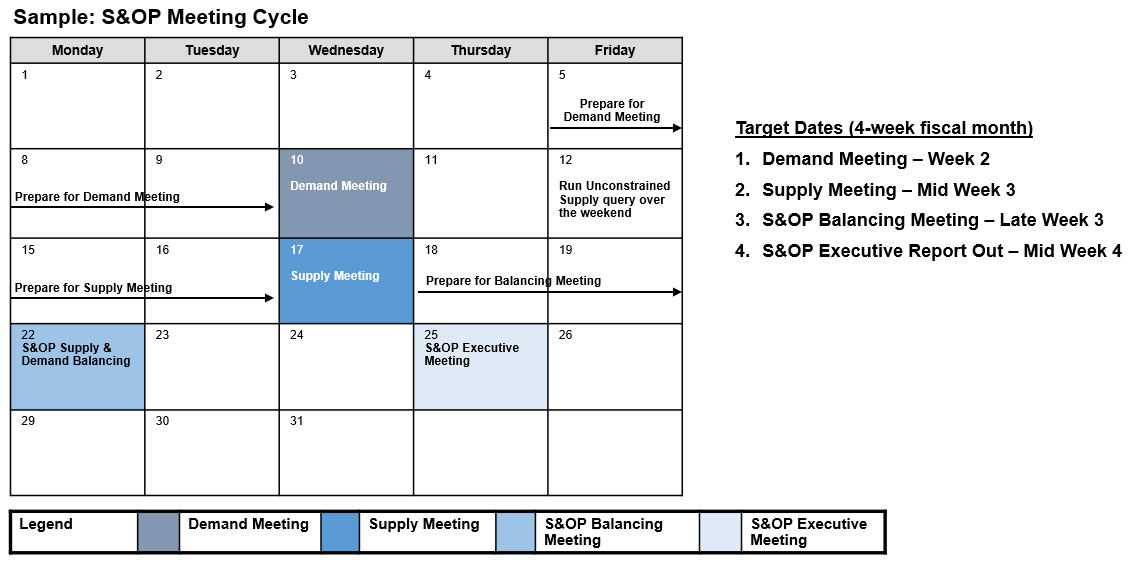

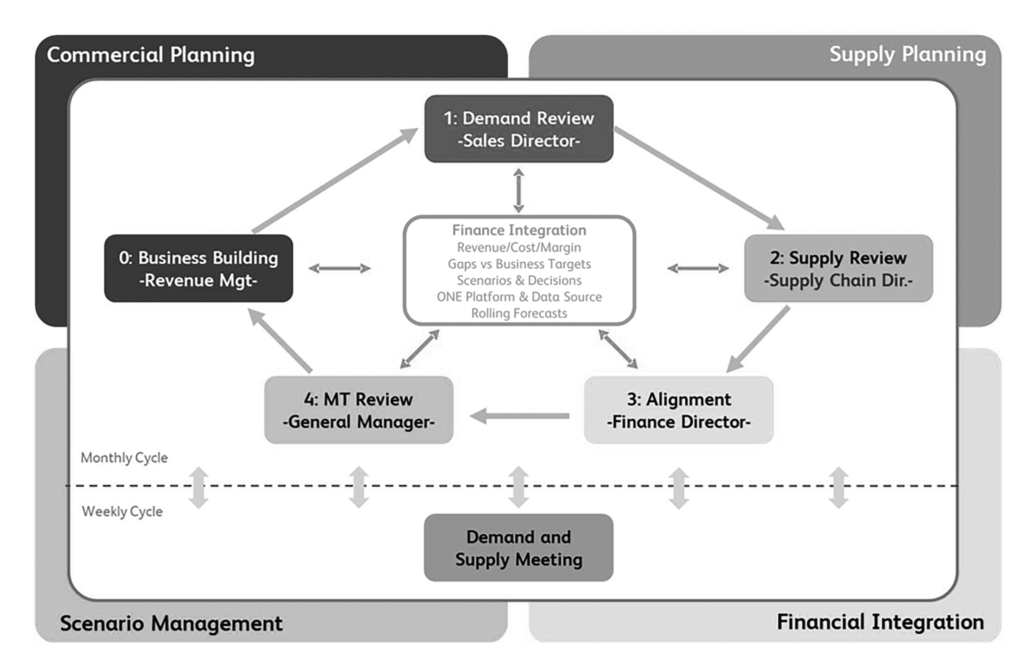

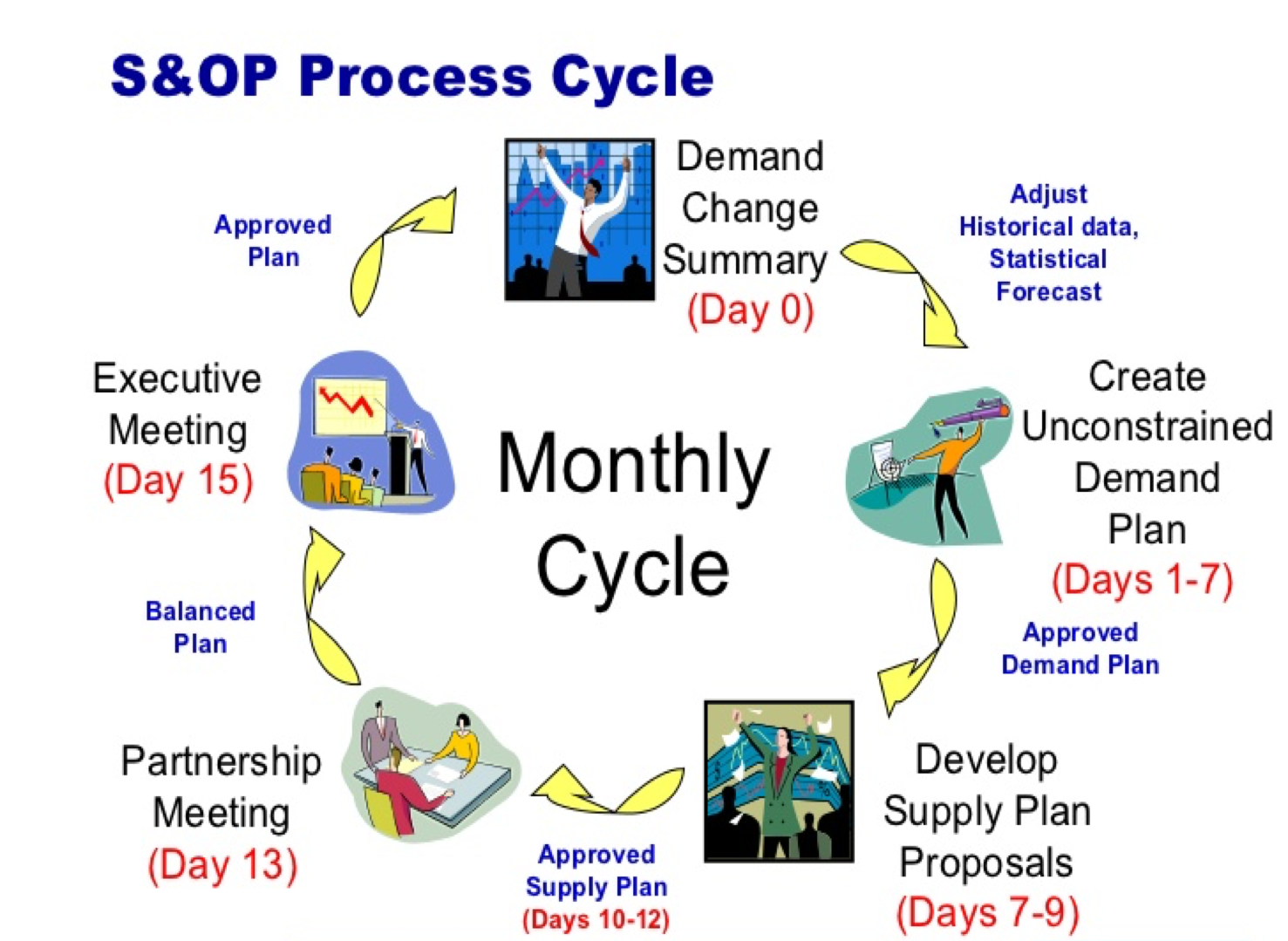

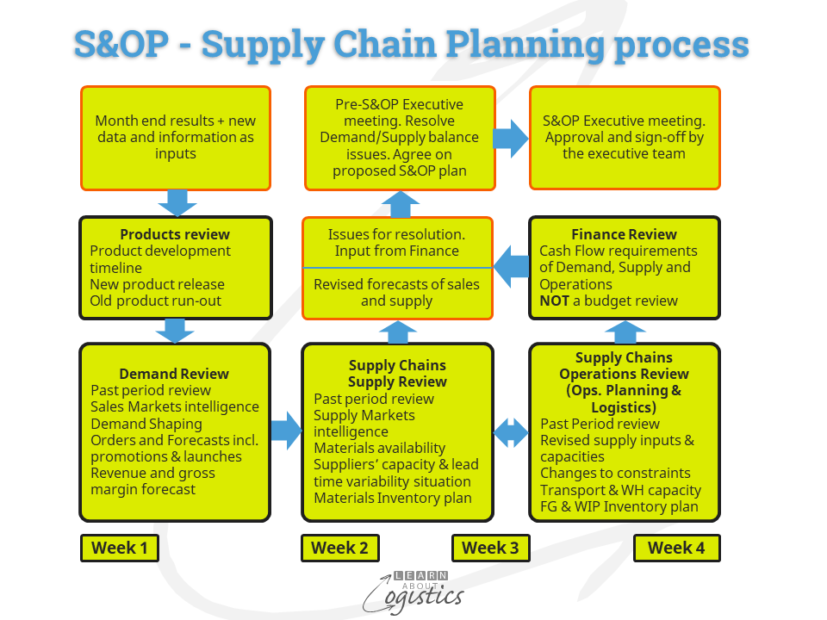

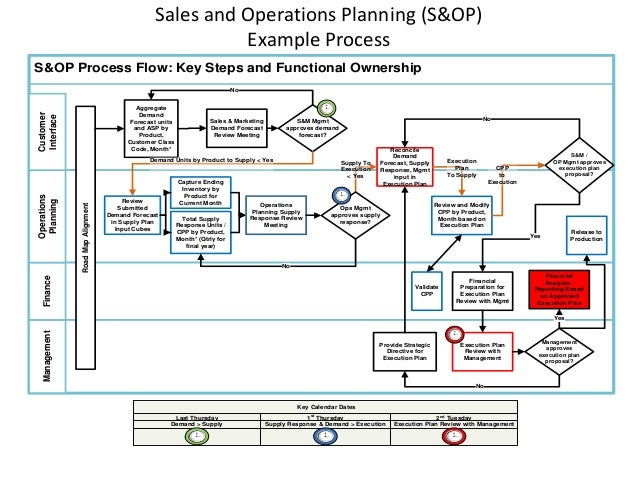

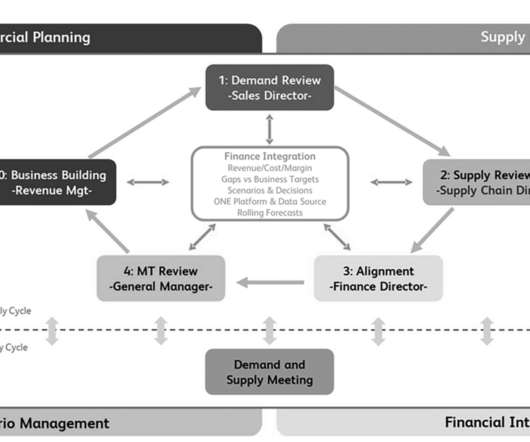

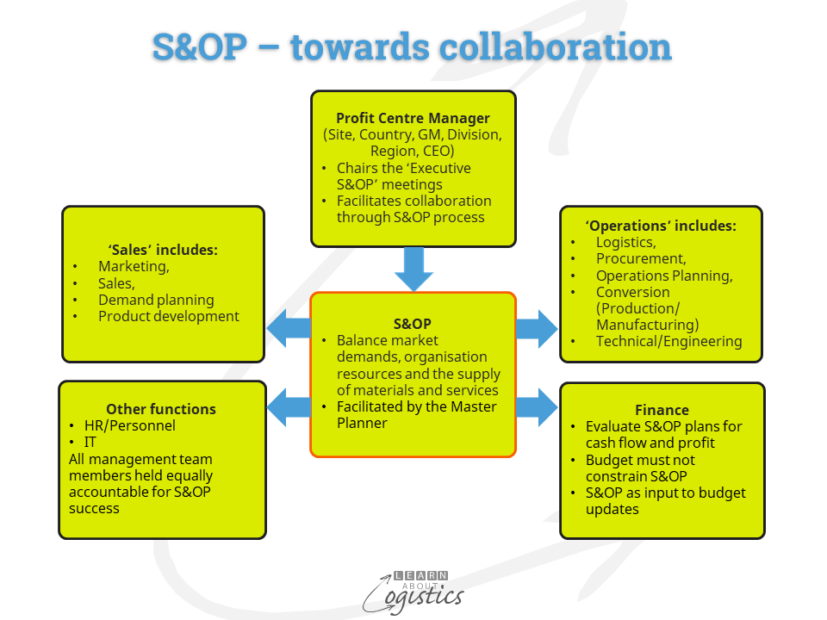

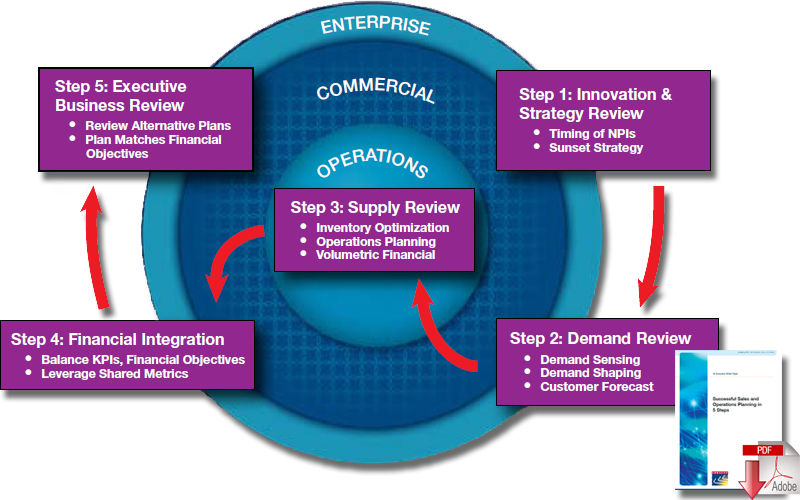

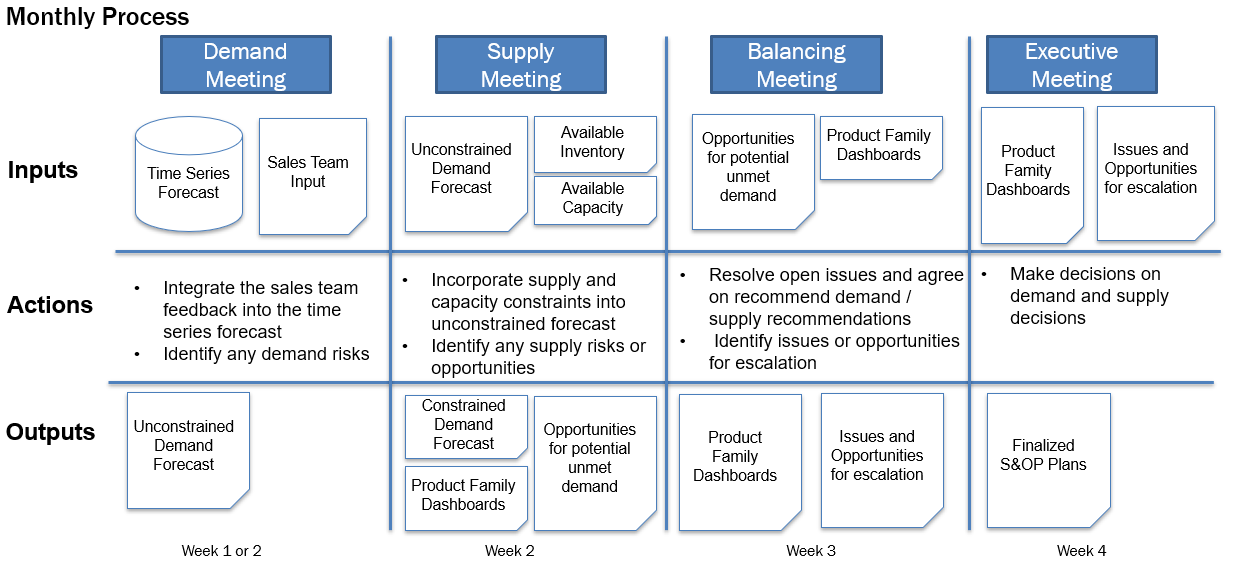

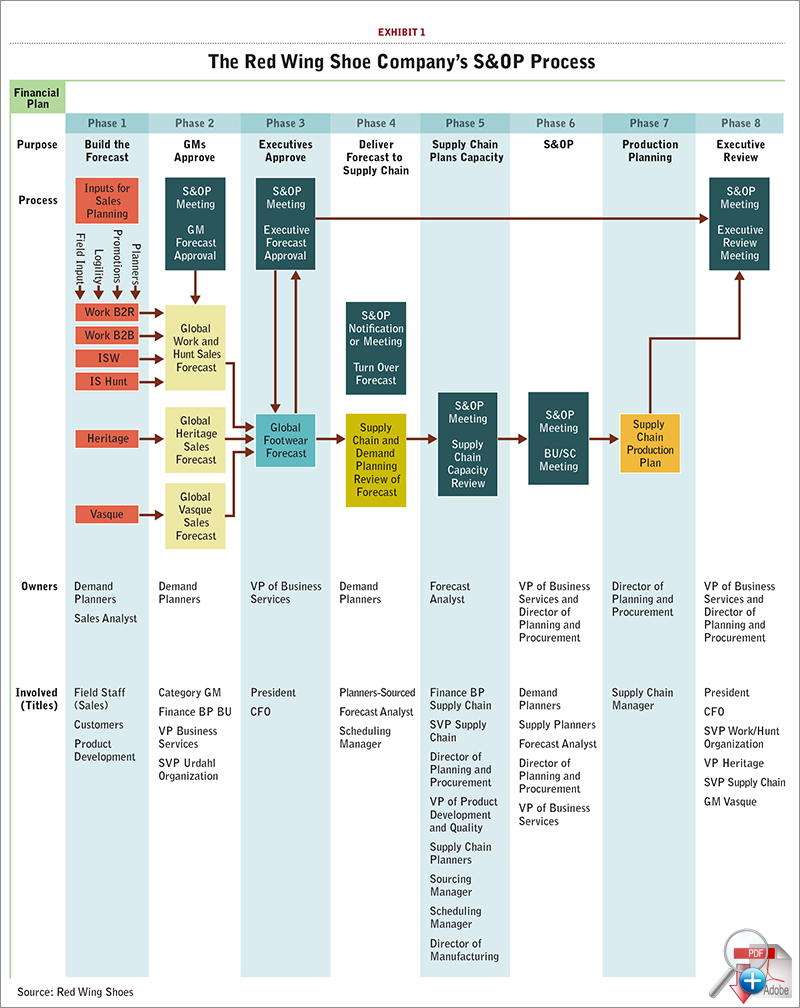

S&OP facilitator helps discover why opinions differ while keeping the S&OP process on track S&OP Silos Potential silo conflicts outside of the S&OP process that hinder S&OP performance conflicts of interest, such as one department lowering its costs by offloading expenses onto another department failure to share information, or•Create the tools –SOP, form, register, process flow •Incorporate risk assessment into process •Train staff in whole process, including risk processes •Ensure procedure is understood and followed •Track progress of each deviation •Ensure timely closure •Periodically review raised deviations •Look for trends, repeat eventsWe recommend using a highlevel SI&OP process that operates on a repetitive monthly cycle The process requires outlining data collection processes, timing and responsibilities of the participants Start by prototyping the key concepts and establishing detailed processes for demand, supply and consensus building

Supply Chain Graphic Of The Week The S Op Process

Sop process flow

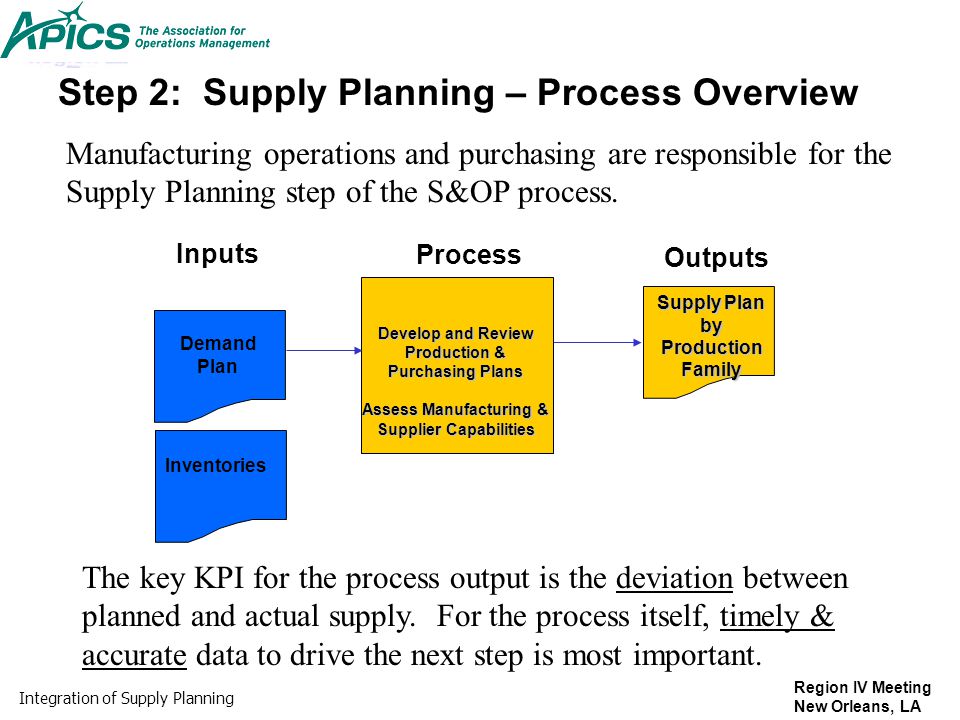

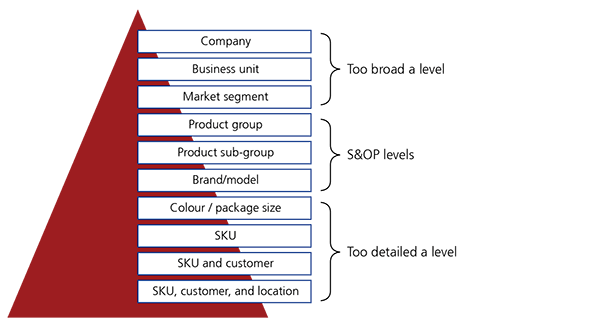

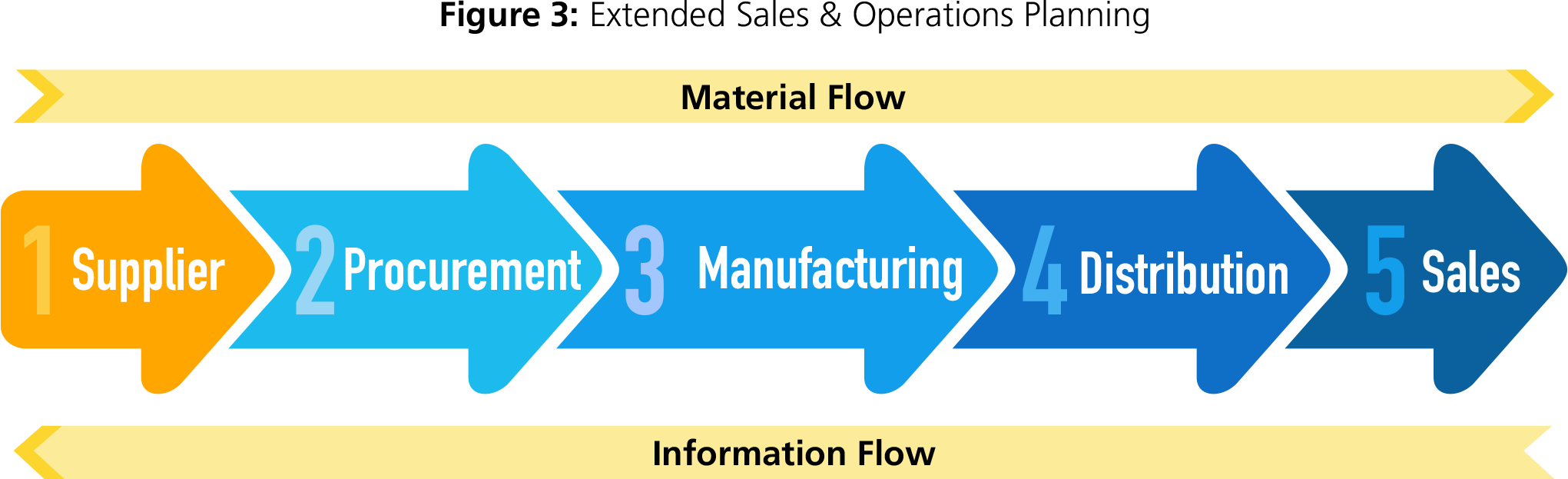

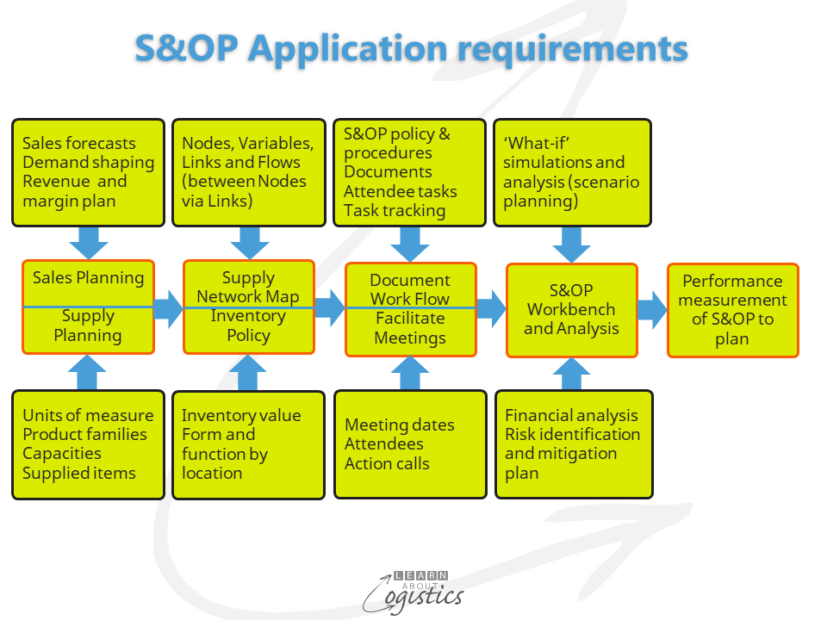

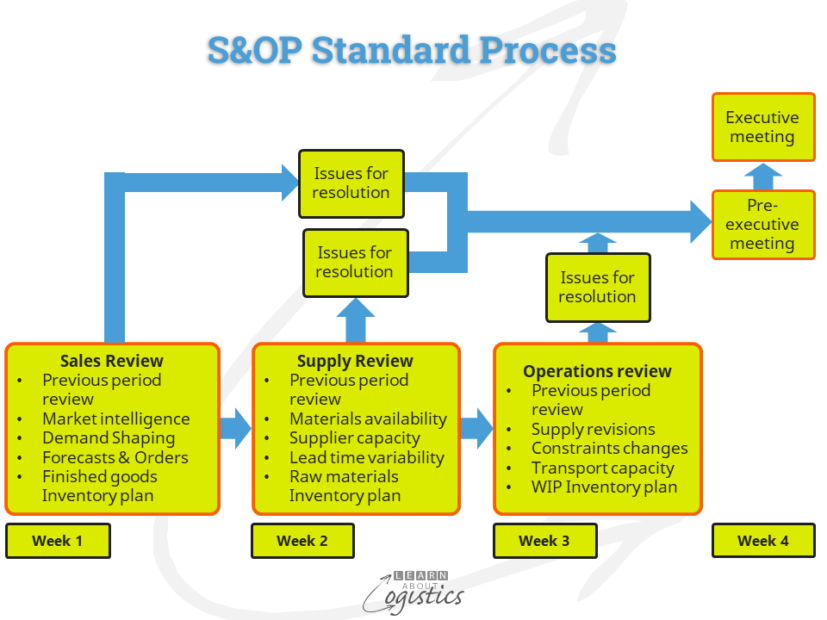

Sop process flow-According to IBF, S&OP is a process that coordinates different areas of the business to meet customer demand with the appropriate level of supply When establishing your process, it is important to consider who will be responsible for each step of the process You will also want to set expectations for handoffs, meetings, and how you will communicate changes Effective S&OPOne of the primary benefits of S&OP is the planning structure Most forecasting processes generate forecasts only using an item's history In contrast, S&OP typically places that data in context, such as within a given market or customer It does so by providing data at an aggregate level across entire groups of customers or product families

Sales And Operations Planning S Op Transform Your Business

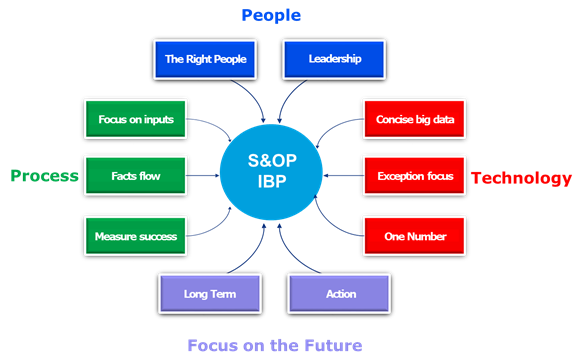

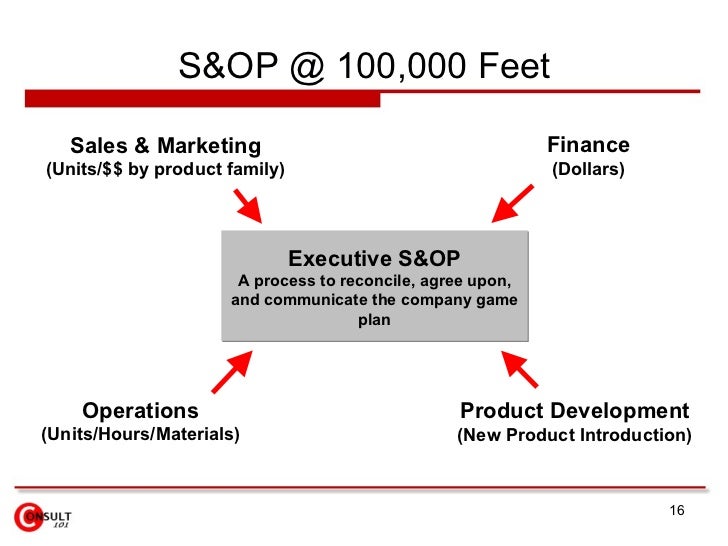

S&OP Challenges Challenges Senior leadership support & "walk the talk" Achieving process compliance Identifying S&OP Champion or expert to lead implementation Clear definition and acceptance of roles and responsibilities, including defining specific objectives in employee appraisals Establishing S&OP meetings as the business priority SOP, Work Instruction, & Procedures How to structure If you look at the documents like a pyramid, then Standard Operating Procedures are the top layer These are often shared with customer and rarely hold confidential data Procedures (second tier) describe the processS&OP, or sales and operations planning, is an integrated business management process that drives organizational consensus to balance supply and demand The S&OP process, which typically happens monthly, aligns operational areas – such as sales, marketing, product development, manufacturing, procurement, finance, and accounting – so they

Standard Operating Procedure Flowchart Template Create your own ProcedureReview process map online in minutes Start with our free templates and accelerate your workflow Begin anywhere with Moqups Click on the example to open the Moqups app and start customizing your diagramThis shape means that there is a flowchart for the predefined process that has already been drawn and you should reference it for more information Punched Card This is the old IBM punched card Each line of a program was punched into one IBM card Then the cards were stacked in order and taken to a card readerA Flowchart showing RW S&OP You can edit this Flowchart using Creately diagramming tool and include in your report/presentation/website Linear Process Template Using Flowchart Objects (18) Vertical Swimlane Flowchart Template with multiple ends 5 (17) Creately is an easy to use diagram and flowchart software built for team

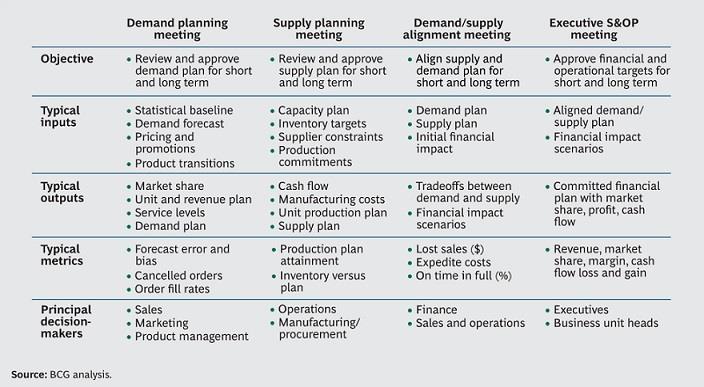

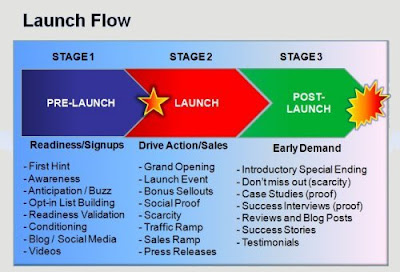

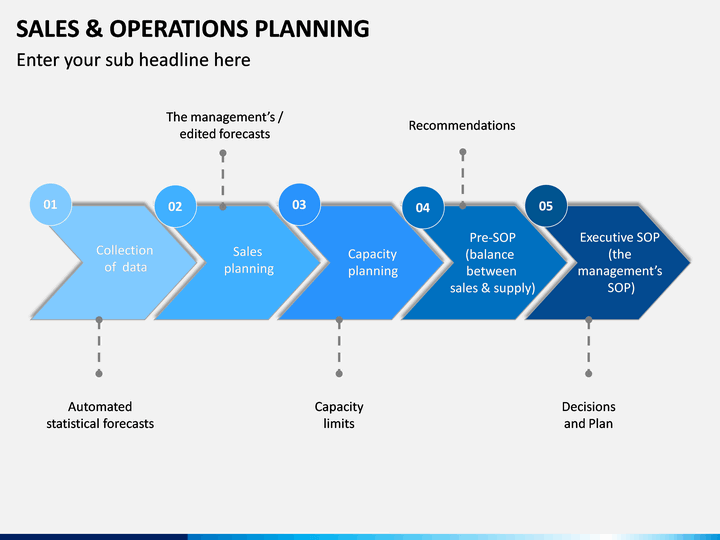

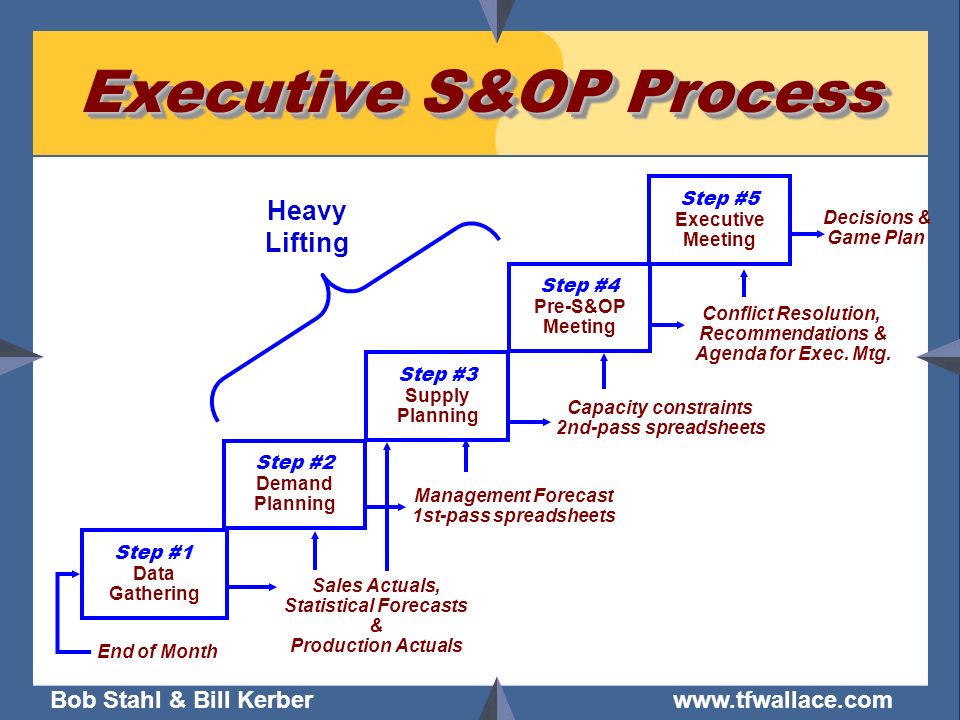

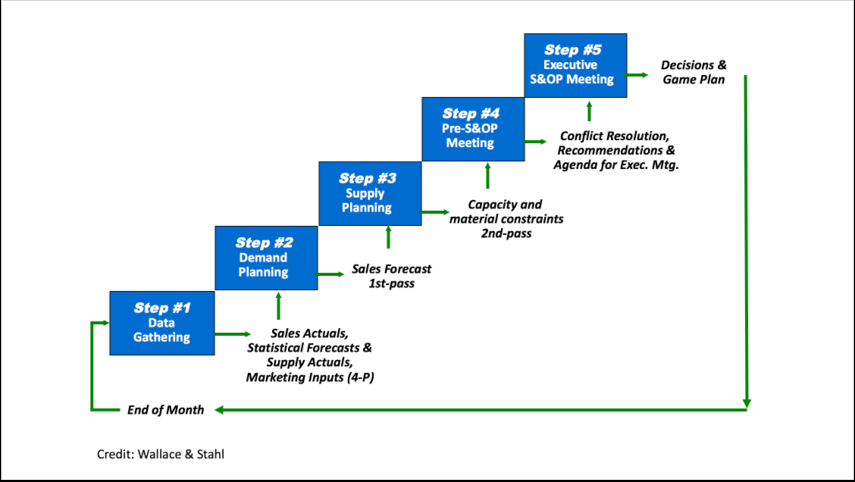

S&OP allows companies to intelligently streamline operations in order to boost profit numbers Common Steps in the S&OP Process The S&OP process can be broken down into six essential steps data gathering and forecasting, demand planning, production planning, preSOP meeting, executive S&OP meeting, and the S&OP strategy implementationWork processes to flow particular outcome—by optimizing the process, getting rid of waste, and adding automation Sometimes, you can even eliminate processes to achieve business objectives Without a systematic approach, you can risk making processes overly confusing and complex, "For us, enhancing the S&OP process is less about change management and more about improving the type and flow of information throughout the organization" —Director of global demand management at a hightech manufacturer

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

Sales And Operations Planning

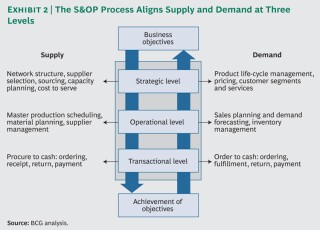

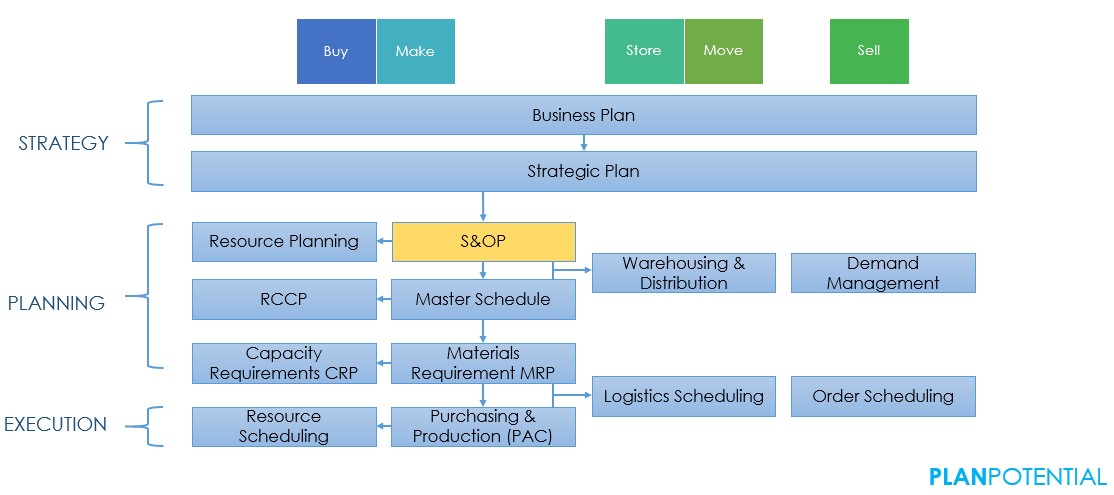

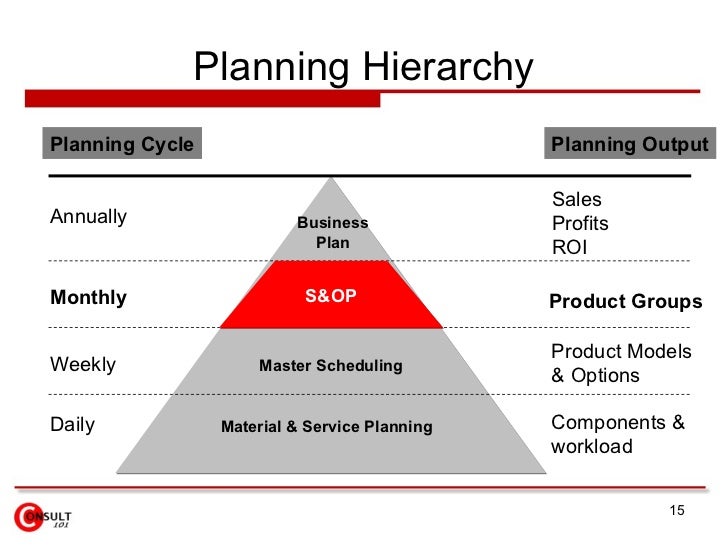

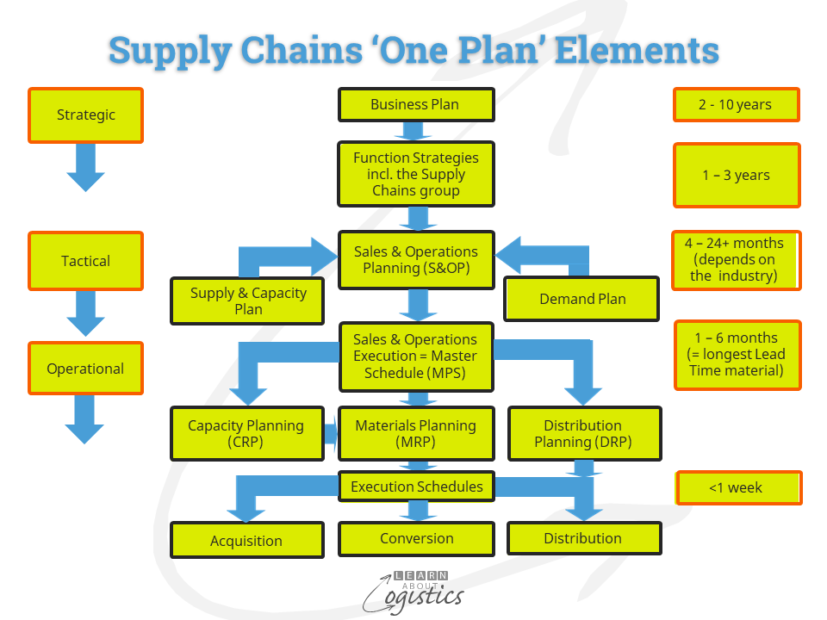

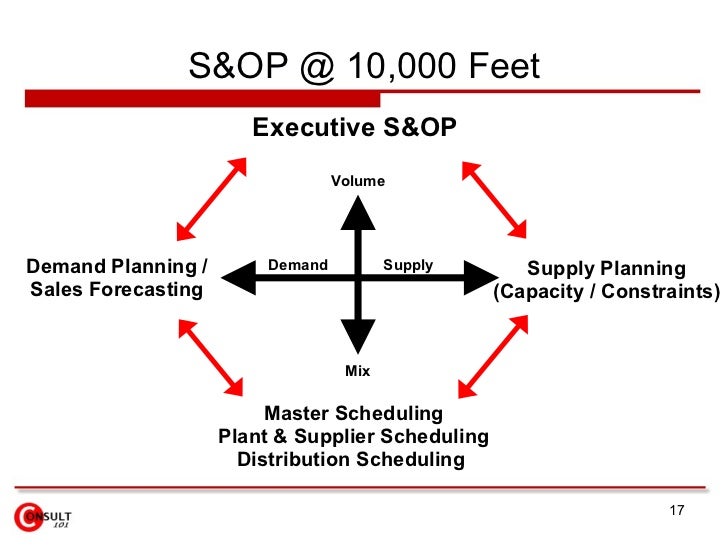

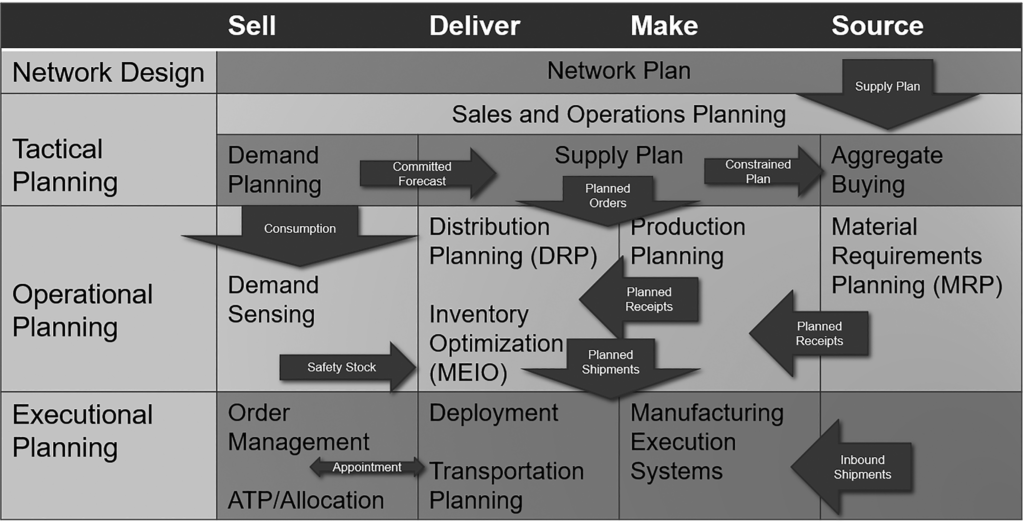

Finalize and implement S&OP The S&OP process includes forecasting, demand and supply planning, and executive review The goal is to coordinate sales and operations planning across business functions so they're all on the same page The exact steps can vary depending on the company, its products, and its industry 1Primary Flow Deploying Plans Down The S&OP process operates within the bounds of the goals, targets and strategic imperatives that have been passed down from the strategic planning processes These goals, targets and strategic imperatives act as guidelines throughout the S&OP process, ensuring that decisions are being made in alignment with Goal of S&OP process The primary goal of the sales and operations planning process is to facilitate the flow of information between demand and supply planning Master planning is concerned with coordinating the supply side of the organization

Sales Operations Planning Two Decades Of Learning At Basf Ppt Video Online Download

Ready To Upgrade Your S Op Process For Industry 4 0

A process flow chart template uses symbols and diagrams to depict complex processes from start to finish Just enter your process data to the Excel flowchart template, then export to automatically create the shapes and connectors that visually tell the story A process mapping template is a helpful tool to study and refine processes to increaseTypes of Standard Operating Procedures Productions and Operations These include instructions on inspecting procedures, production line steps, and maintenance of types of equipment Finance and Administration These contain guidelines on the collection and billing process and maximizing cash flow while meeting all payment deadlines A simple chart which outlines the S&OP (Sales & Operations Planning) business process flow, including the core outcomes of the regular monthly S&OP Meeting FOOD, BEVERAGE, CONSUMER PRODUCT GOODS (CPG) Management Professional (Retail and

A Comprehensive Overview Of Sales And Operations Planning S Op

Sales And Operations Planning S Op Transform Your Business

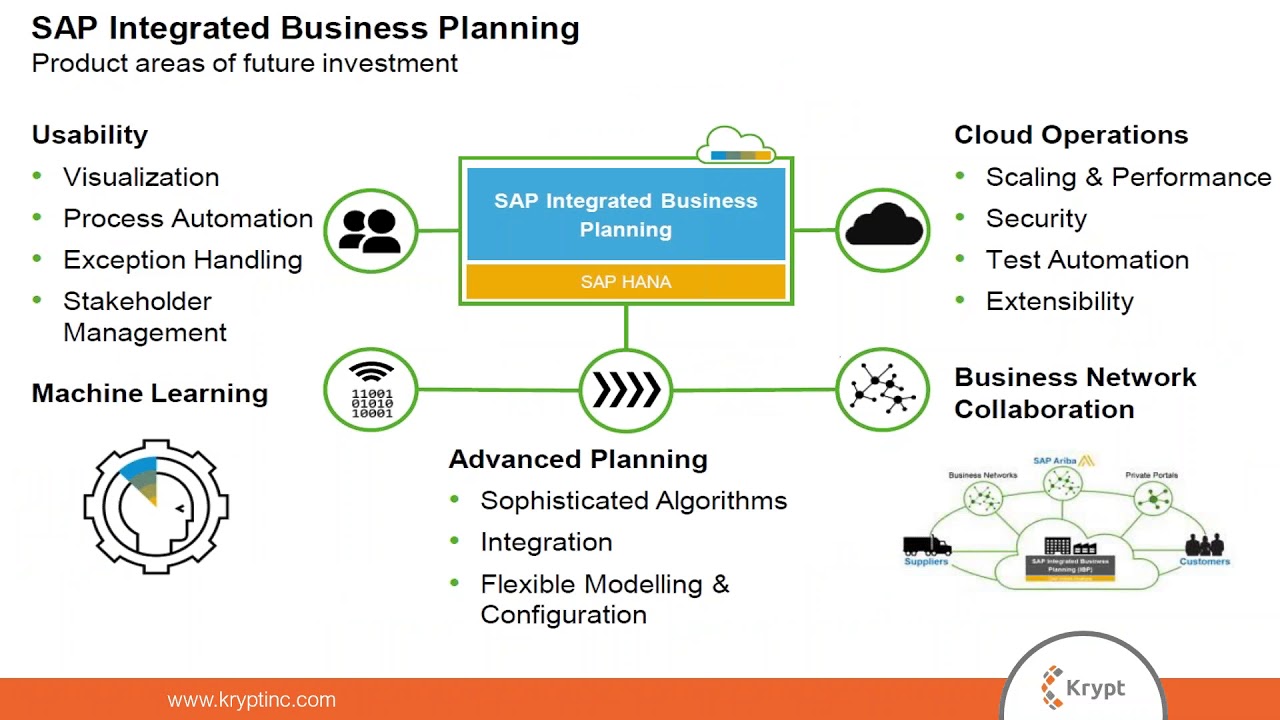

S&OP Process flow with tools Production Disaggregation Logic Production plan @ sku level BW ECC Transportation Lane Volume TCP SAP STR's MP Production Volume SAP Planned Orders Planned Orders for Distribution and Dependent Demand BU Finance SC Finance DP SNP –Heuristics At sku level SNP –Optimizer At aggregate level AOP Version in SAP S&OP Process Flow admin 0 Comments 0 admin The S&OP process has various steps to arrive at a final plan, and it starts with data gathering Related Posts Patience is a Virtue, Especially When Implementing an The post 'Integrating the S&OP Process Go with the Flow!' by Mark Pearson appeared first on The Planning Blog If you liked this post, click the follow button above this article or check out more

Sales And Operations Planning Relex Solutions

Sales And Operations Planning S Op Is All About Balancing Supply And Demand Implement Consulting Group

Learn exactly what a business process is in this definitive guide to business process What is an SOP (Standard Operating Procedure)? Sales and operations planning (S&OP) is a popular process that aligns a company's diverse functions while balancing supply and demand S&OP gives executives a comprehensive overview of the business so they can grasp where it stands (in all its complexity) A Sales, Inventory and Operations Planning (SIOP) business process is an essential element for running a successful business SIOP will allow you to improve your forecasting, capacity and resource planning, cash flow, and inventory levels Yet there are many challenges with getting a proper, functioning SIOP process in place

S Op The Evolving Supply Chain Lifeline Supplychainomics

S Op Process

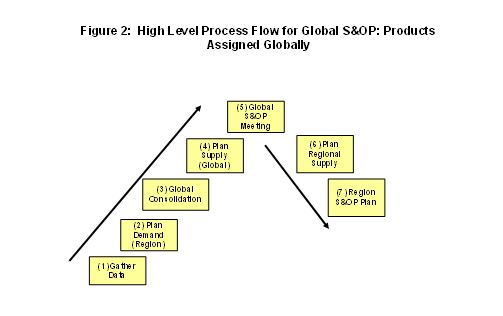

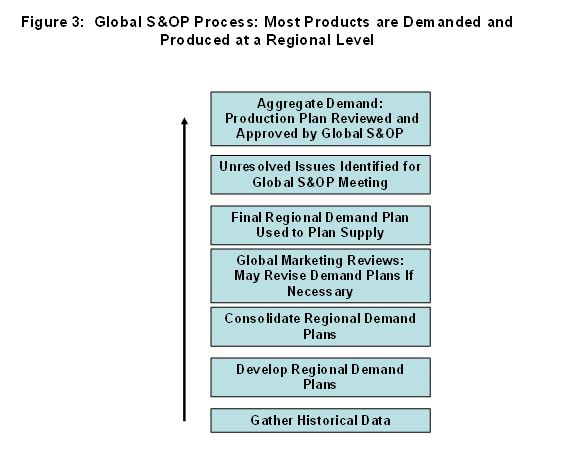

Steps to S&OP There are two distinct phases to S&OP 1) process design, and 2) process conduct In the design phase, all of the technical workings are engineered, and in the conduct phase S&OP is used as a business management process The following 10 steps describe how to go about these two phases Steps 15 are design and steps 610 are conduct 1 S&OP is a process that coordinates different areas of the business to meet customer demand with the appropriate level of supply Implementation of S&OP should be undertaken in phases Most businesses start with a pilot program in one business unit in one country, for example Flowchart SOP Template (IT) Use a Flowchart Standard Operating Procedure (SOP) to draw out more complex processes This type of SOP requires numerous decision points which affect the direction of the task, for which flowcharts are very useful Flowchart SOPs may have to be referenced in an emergency and so must be easily read and understood

Achieve Excellence In Sales And Operations Planning Sapinsider

S Op In Las Vegas Let S Learn Laugh And Be Entertained At The S Op Innovation Summit

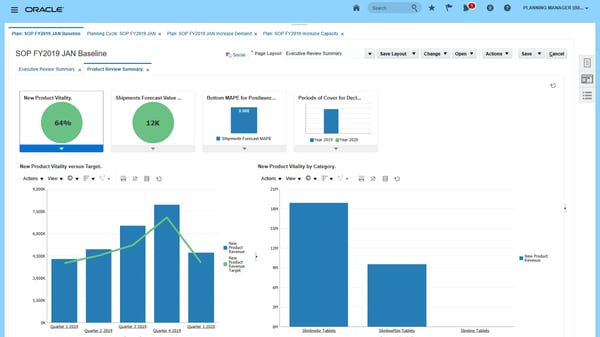

S&OP is gaining attention among organizations eager to implement powerful tactical management processes to help them succeed while navigating a rapidly changing business landscape Short for Sales and Operations Planning, S&OP is an integrated business management process that aligns all facets of an organization to their key market goals, synchronizing them and allowing the S&OP deals with the continuous change that occurs in the business and is a process to effectively manage ongoing change In practice, it is called a replanning process S&OP is owned by the GM or CEO It is a crossfunctional process and includes all the functions of the company Correctly implemented, it is a demand and strategydriven processS&OP Work Flow Use IBM Cognos 8 BI to analyze results throughout the S&OP process The IBM Cognos S&OP Performance Blueprint facilitates • Reforecasting demand • Balancing the production plan to the fulfillment and distribution plan • The consensus meeting • The executive review meeting • Strong linkage to financial objectives

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

What Are The Basic Elements Of The S Op Process Quora

In a cellular or flowline based operation, SIOP provides the daily run rates for these product families SIOP is the key business process that derives from the strategic plan, and from which scheduling, order promising, material, shop floor control, and many other processes derive70 FLOW CHART PROCESS OVERVIEW Please refer to the SOP Approval Process Flowchart link in Section 10 80 PROCEDURE 81 Conduct a Needs Assessment Determine what procedures require documentation The current procedure in place for determining what procedures or processes need to beProcess Flowcharting for SOP Development, Implementation, Training and Maintenance By Lorrie D Divers Standard operating procedures (SOPs) are "detailed, written instructions to achieve uniformity of the performance of a specific function" 1 SOPs help ensure consistent high quality and regulatory compliance

The Fully Integrated S Op Of A Multi Site System In Supply Chain Download Scientific Diagram

Scm Awareness S Op Process Planpotential

The overall objective of the S&OP process is to agree on an aligned set of feasible functional plans and targets for the next 18 – 24 periods,Standard SOP Process flow Sales & Operations Planning (SOP) is a flexible forecasting and planning tool with which sales, production, and other supply chain targets can be set on the basis of historical, existing, and estimated future data The first step for the supply chain planning leader is to identify the S&OE content in the S&OP process and move it to a separate agenda As a rule of thumb, anything that covers the nearterm horizon, commonly 0 to 3 months, is S&OE It deals with all the issues stemming from actual demand and supply — the reality of supply chain that is

Supply Chain Graphic Of The Week The S Op Process

Integrating Suppliers In Sales Operations Planning Whitepaper On S Op Process Gep

Standard operating procedures serve as a road map for a business, providing stepbystep instructions for how routine activities must be handled"Human resource management (HRM, or simply HR) is the management process of an organization's workforce, or human resources It is responsible for the attraction, selection, training, assessment, and rewarding of employees, while also overseeing organizational leadership and culture and ensuring compliance with employment and labor laws When designing the process map, make sure you cover all scenarios so the process flow and all intermediate activities are mapped Conclusion A business process will typically produce one or more outputs to the business, either for internal use of

S Op Process Flow Biel 10 27 11

Case Study The Benefits Of Sales Operations Planning S Op Supply Velocity

S&OP develops a midrange plan to operations using input from top management The plan identifies key resources to achieve the firm's strategic objectives and goals, and is the basis of all subsequent material and labor resourceInformative video describing the S&OP Process as it relates to SAP IBP Krypt, Inc is your consulting partner for implementing SAP IBP

8 Flowcharts For Traditional Planning Versus Advanced S Op Download Scientific Diagram

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

Dp Vs S Op Process Flow

Integrating The S Op Process Go With The Flow Business 2 Community

Introducing Sap Ibp S Op Processes Webinar Youtube

Tactical Sales And Operations Planning A Holistic Framework And A Literature Review Of Decision Making Models Sciencedirect

Integrating The S Op Process The Planning Blog

Gartner Blog Network

Applications Requirements That Assist S Op Decisions Learn About Logistics

1

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

S Op Process

What Is One Plan S Op Arkieva

A Comprehensive Overview Of Sales And Operations Planning S Op

S Op Process

Sales And Operations Planning In The Process Industry A Literature Review Sciencedirect

Toc4u Focus 17

S Op Process Post1 New Product Planning Process Oracle Value Chain Planning Blog

Sales And Operations Planning In Manufacturing Manage Collaboration Across The Entire Organization Tompkins Solutions

What Is S Op How S Op Works Demand Planning Com

2

Configurable Products Planning Sap Ibp Enhancement For Make To Order Mto Industries Sap Blogs

2

S Op More Important For Planning New Era Supply Chains Learn About Logistics

Driving Supply Chain Agility With S Op And S Oe I Kinaxis

Integrating The S Op Process Go With The Flow Online Sales Guide Tips

S Op Is The Hub Of Supply Chains In Your Business Learn About Logistics

Sales Operations Planning Why Is S Op Important

1

S Op Process

The Effect Of Sales And Operations Planning S Op On Supply Chain S Total Performance A Case Study In An Iranian Dairy Company Sciencedirect

Generalized Scor Implementation

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

S Op Heuristics Flow Chart Download Scientific Diagram

A Comprehensive Overview Of Sales And Operations Planning S Op

S Op Software Sales And Operations Planning Qad Dynasys

2

1

2

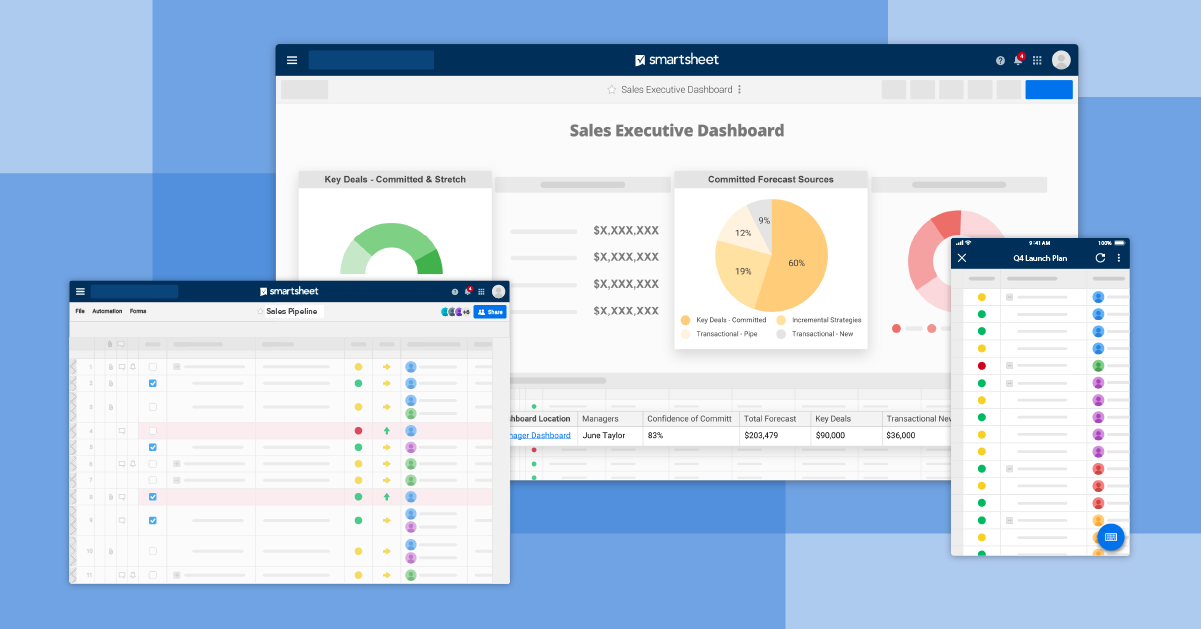

Sales And Operations Planning S Op 101 Smartsheet

Examples And S Op Supply Chain Brief

Sales Operations Planning A Proven Business Process Learn About Logistics

Sales Operations Planning S Op Sap Library Sales Operations Planning S Op

Sales And Operations Planning Powerpoint Template Sketchbubble

Sales And Operations Planning Relex Solutions

The 5 Most Common Sales Operations Planning Mistakes And How To Avoid Them Supply Chain 24 7

Using Retail S Op To Make The Holiday Season Smoother And More Profitable Multichannel Merchant

The S Op Lean Connection Making Lean Work With Demand Variability Ppt Download

S Op Heuristics Flow Chart Download Scientific Diagram

A Comprehensive Overview Of Sales And Operations Planning S Op

The Effect Of Sales And Operations Planning S Op On Supply Chain S Total Performance A Case Study In An Iranian Dairy Company Sciencedirect

A Common S Op Process For Your Business Helps Planning Learn About Logistics

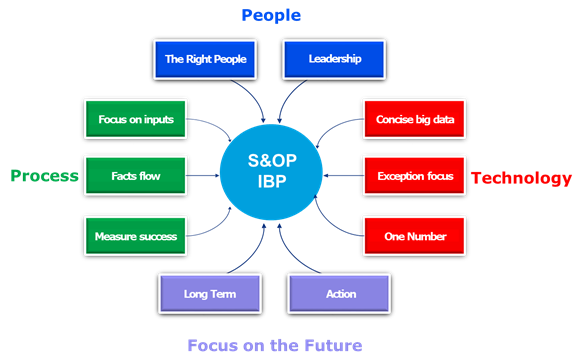

3 Primary Components Of Sales Operations Planning People Process And Technology Supply Chain 24 7

Sales And Operations Planning Myths Part 2 Supply Chain 24 7

2

What Is Sales And Operations Planning S Op Plex Demandcaster

Sales Operations Planning Consulting Supply Velocity

S Op Heuristics Flow Chart Download Scientific Diagram

Sales And Operations Planning S Op Is All About Balancing Supply And Demand Implement Consulting Group

Seven Steps To Support A Sustainable S Op Culture Supply Chain Minded

S Op Process

Sales And Operations Planning Explorescm

S Op Sales And Operations Planning And Sco

The Effect Of Sales And Operations Planning S Op On Supply Chain S Total Performance A Case Study In An Iranian Dairy Company Sciencedirect

3 Primary Components Of Sales Operations Planning People Process And Technology Supply Chain 24 7

S Op Made Good The Importance Of Investing In People Reuters Events Supply Chain Logistics Business Intelligence

Achieve Excellence In Sales And Operations Planning Sapinsider

What Is S Op How S Op Works Demand Planning Com

Sitmi Science Industrial Technology And Management Intelligence S Op Sales And Operations Planning Process Flow Simple And Quick Explanation Of Each Steps Facebook

S Op Heuristics Flow Chart Download Scientific Diagram

What Is S Op How S Op Works Demand Planning Com

Sales And Operations Planning S Op 101 Smartsheet

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

What S Holding The S Op Process Back Part Two Establishing A Business Efficiency Planning Process That Works Chainalytics

The S Op Framework S Process For Implementation Download Scientific Diagram

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

The Fully Integrated S Op Of A Multi Site System In Supply Chain Download Scientific Diagram

Pdf Sales And Operations Planning S Op An Overview

Gartner Blog Network

S P Process Flow Demand Planning

The Production Planning Pp Or Sales And Operations Planning S Op Download Scientific Diagram

What Is S Op How S Op Works Demand Planning Com

S Op Application Flow At A Glance Sc Navigator

1

0 件のコメント:

コメントを投稿